International range

Valiant 600

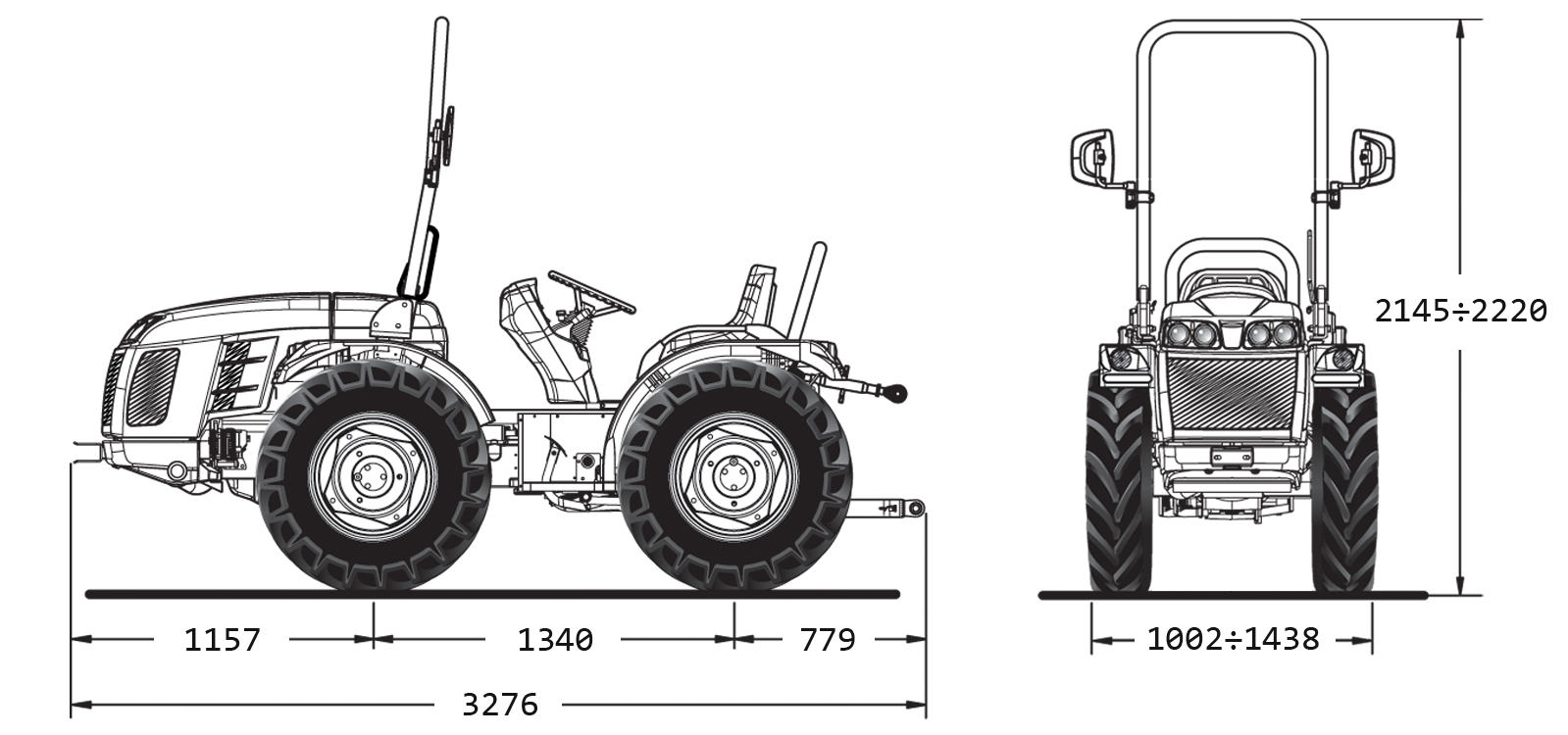

49 hp (Stage IIIA) isodiametric tractor. Narrow wheel track, compact dimensions and reduced turning radii.

Valiant 600 AR is a multi-functional and compact isodiametric tractor designed to work in extremely tight spaces: row crops, vineyards, orchards, greenhouses and nurseries.

The OS-Frame and the power steering acting on the central joint of the tractor ensure agility between the rows and reduced turning radii.

The reversible driving position (optional) makes it possible to work in a practical and safe manner both with towed and front-mounted attachments.

Transmission

12+12

POWER

49 hp

Driving position

monodirectional / reversible

MIN. WIDTH

1002 mm

Technical Data

Valiant 600 - AR

| Type | Isodiametric with footstep driving position |

|---|---|

| Chassis | Articulated |

| Driving position | Monodirectional or reversible |

| Transmission | 12 + 12 |

| Synchronized reverser | Yes |

| Drive | Permanent 4WD |

| Hydraulic system | Dual circuit with independent pumps |

| Joystick | n/a |

| Rear lifting capacity (kg) | 1200 (at the ball joint) |

| Front lift | n/a |

| PTO rotation speed (rpm) | 540 |

| PTO engagement control | Electro-hydraulic |

| Service brakes | Multidisc in oil bath, acting on the rear wheels |

| Cabin | n/a |

n/a = not available