Rotex XR

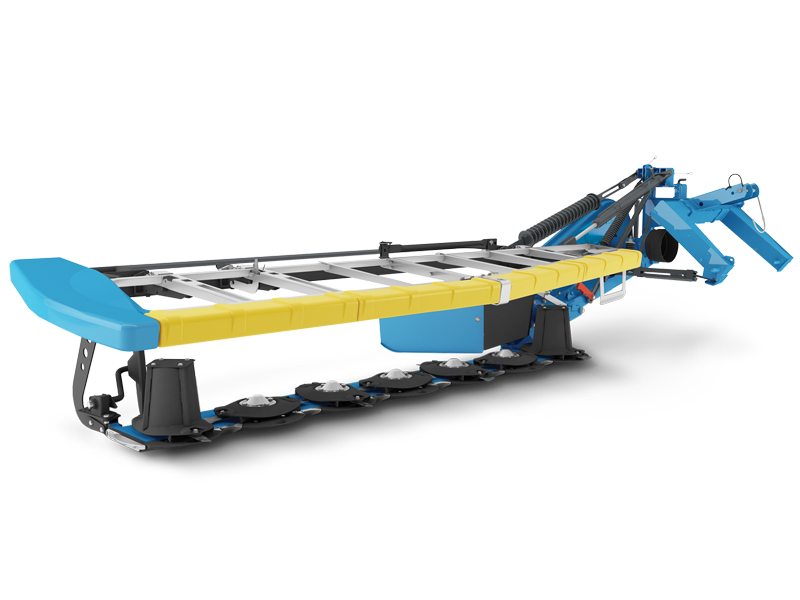

Rear-mounted disc mower with chevron roller conditioner.

Range of rear mower-conditioners intended for intensive farming for mowing and conditioning fodder on medium and large areas.

The contained weight and the perfect balance of the bar make the Rotex XR applicable to all tractors as well as in combination with front-mounted mowers.

R | Roller conditioner

Thanks to the chevron roller conditioner that operates across the entire cutting width, the grass is crushed, without however losing the nutrient-rich leaves, and deposited on the ground forming a large and well-ventilated heap.

This process reduces drying time by up to 50% to the advantage of the quality of the fodder and the lower risk of exposure to bad weather.

Technical Data

Rotex XR - XR5

| Assembly | Rear |

|---|---|

| Type | Disc mower-conditioner |

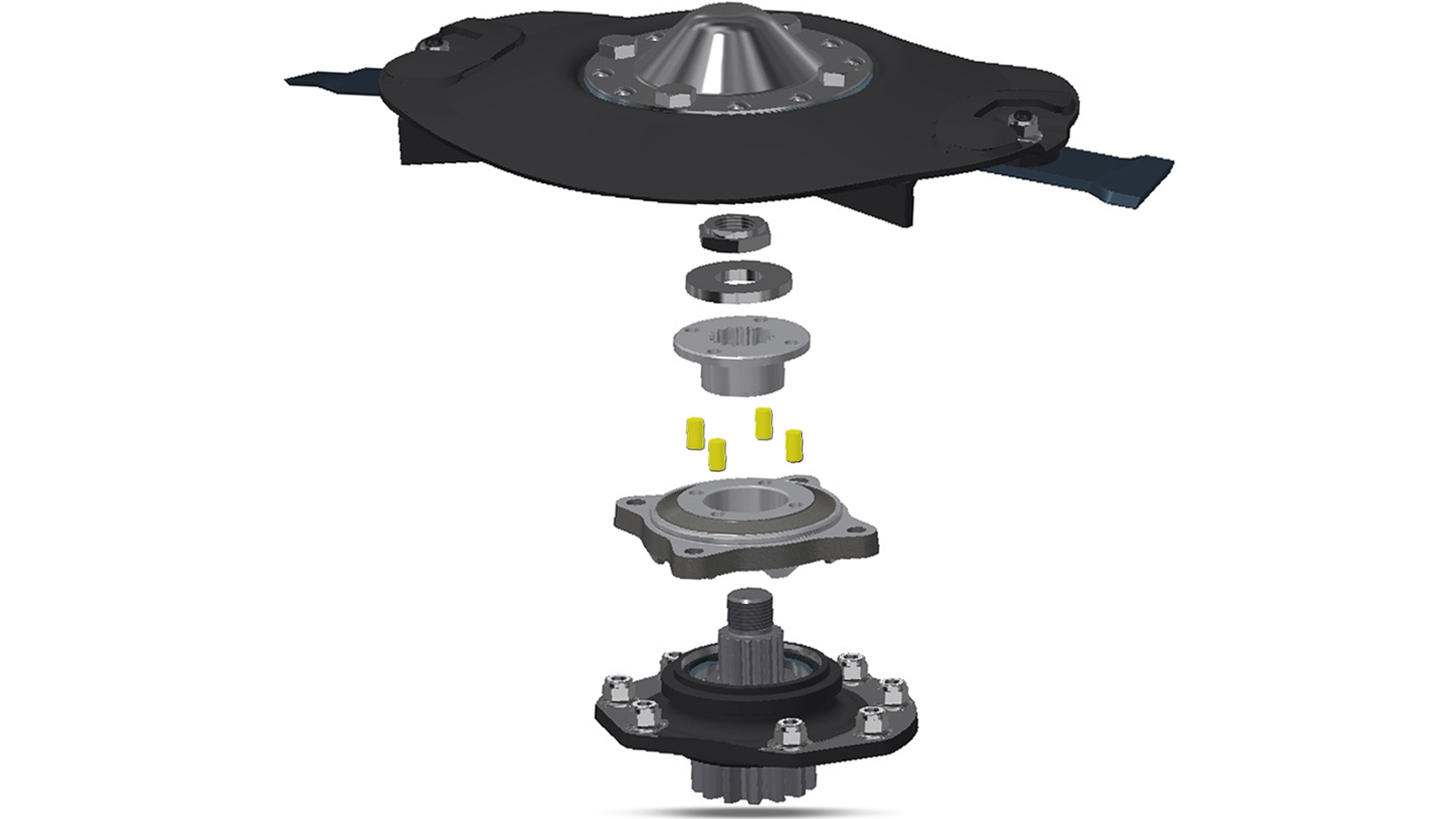

| No. of discs | 5 |

| Cutting width (mm) | 2050 |

| Conditioner | Chevron roller |

| PTO power (HP) | 54 |

| Hydraulic lift | Standard |

| Weight (kg) | 720 |