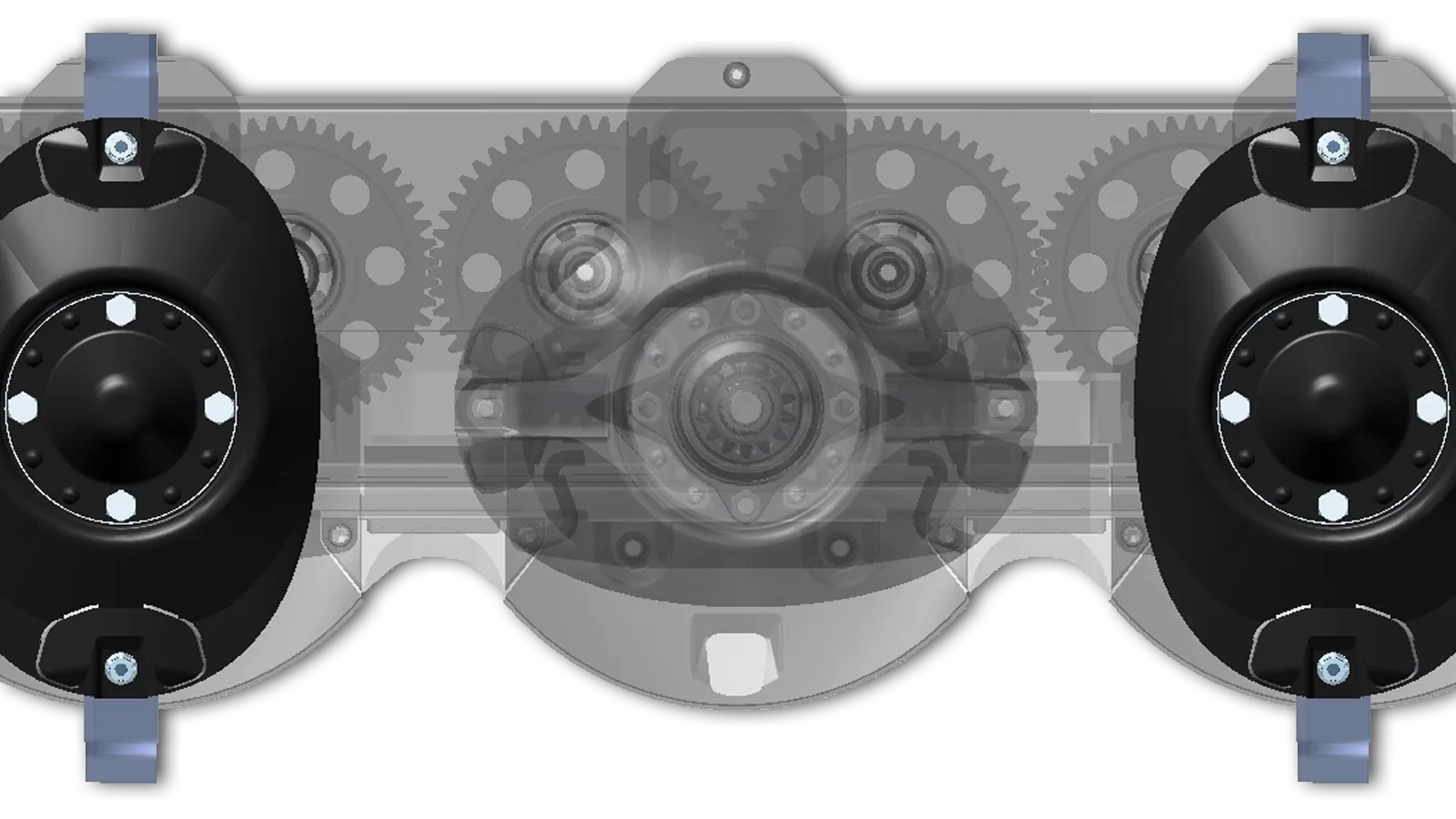

Disc mowers

Rotex XT

Rear-mounted disc mower for small and medium-sized farms.

Range of reliable and highly performing rear-mounted disc mowers for mowing fodder on small and medium-sized areas.

The minimum power required from PTO makes the Rotex XT applicable to low power tractors as well as in combination with front-mounted mowers.

No. of discs

7

CUTTING WIDTH

2.85 m

WEIGHT

645 kg

PTO POWER

48 hp

Focus

Thanks to the robust cutter bar, with working widths from 1.65 to 2.85 m, and the reduced pressure to the ground, the Rotex XT ensure a clean cut, optimal nutritional value maintenance and a well-preserved lawn to the benefit of a superior quality fodder.

Technical Data

Rotex XT - XT7

| Assembly | Rear |

|---|---|

| Type | Disc mower |

| No. of discs | 7 |

| Cutting width (mm) | 2850 |

| Conditioner | No |

| PTO power (HP) | 48 |

| Hydraulic lift | Standard |

| Weight (kg) | 645 |